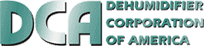

Different heat sources offer different advantages, and choosing the right one for every application can increase efficiency and effectiveness, as well as decrease costs.

At Dehumidifier Corporation of America (DCA), we specialize in optional add-on high-quality heating. Read through this guide for an in-depth comparison of gas duct furnaces vs. electric duct heaters. It’s not enough to know the specifications of one system or the other. Instead, we take a close look at the differences between the two systems so you can choose the best fit with confidence.

Comparing Gas Duct Furnaces to Electric Duct Heaters

As you assess the relative advantages of gas duct furnaces and electric duct heaters, consider key elements like cost, time demands, and potential applications. These core differences can point you toward the right system for your needs.

Electric Duct Heaters

- Configurations: Electric duct heaters can be had in both horizontal and vertical orientations, as well as a wide range of sizes, making them a more flexible option and are installed either in the ductwork or mounted outside the dehumidifier over the blower or outdoor applications as needed.

- Installation: These heaters can be installed in virtually any location, and installers can mount them either directly to the blower (EDH) or in ductwork (EDHS). They are also cheaper to install than gas alternatives.

- Upfront Cost: The equipment itself is also less expensive than equivalent gas units.

- Operational Costs: Electric duct heaters are much more expensive to operate than gas heaters and other units. On average, with today’s cost of natural gas compared to electricity and the area you may live in, a general rule of thumb is electric duct heaters cost three to four times more money to operate than natural gas.

- Voltage: DCA can meet your specific voltage needs whether application is commercial, or residential:

- 208/230/240 V single-phase

- 208/230/460/575 V three-phase

- Applications: Electric duct heaters work well in virtually all commercial and industrial locations. Along with providing environmental room heating, these heaters can also temper outdoor incoming make up air to the dehumidifier. When a very specific temperature is needed electric heating along with a control system designed for that purpose is needed. However, when large amounts of room heating is needed gas duct furnaces or hot water built in coils with an attending gas or oil boiler can be the better choice.

- Testing: Safe reliable electric duct heaters must comply with strict UL listed safety standards, which are well-known across the industry.

- Electric duct heaters can be supplied for both indoor and weather-proof outdoor applications.

Gas Duct Furnaces

While gas duct furnaces can provide similar performance, there are key differences:

- Fuel Source: Gas duct heaters can operate on either natural or LP gas (propane).

- Voltage: Most gas heaters use 115 V single-phase current. This is the standard in households. But they can also be ordered with optional control step down transformers for

- 208/230 V single-phase

- 208/230/460/575 V three-phase

- Indoor or Outdoor Installation: Like electric units, gas duct furnaces can be installed in both indoor and outdoor environments.

- Regular Maintenance: Gas furnaces require normal maintenance where electric duct heaters are normally maintenance free to a point.

- Safety Concerns: Since gas duct furnaces involve combustion, the flue products are vented outdoors with a class B vent. For hazardous applications both the combustion air and the flue products (two pipe system) terminate outdoors.

- Operational Costs: Gas duct furnaces are much less expensive to operate than electrical units, at a scale of three to four times more cost-effective. While fuel prices will vary based on region, natural or LP gas (propane) is the less expensive option under most circumstances.

- Installation: Gas Duct Heaters are not Approved for Residential Applications. Gas duct furnaces don’t offer the same flexibility as electric duct furnaces. These optional units must be mounted in the ductwork outside the dehumidifier and must be vented outdoors. The initial cost of a gas furnace compared to an electric duct heater is considerably higher but payback can be much shorter when large amounts of room heating is needed.

- Certification and Testing: Gas furnaces must comply with UL testing standards or The American Gas Association testing standards.

- Applications: Gas heaters are commonly used in commercial and industrial contexts. They are NOT listed or approved for residential applications. However, DCA provides a hot water coil application using a gas or oil fired hot water boiler. Contact Our Experts for Your Duct Heating Needs

Choose DCA for premium add-on duct heater solutions. Our team is here to help match your facility’s needs with the right electrical or gas solution that fits your budget, application, and space demands.

Since 1995, it’s been our mission to offer high-quality solutions and cutting-edge technology at the right price. We offer an extensive range of add-on duct heaters both gas and electric. Reach out today to learn more about which solution is right for your facility, or request a quote to start your order.

Topics: Uncategorized